T410H-6T Product Overview

Introduction

The T410H-6T is a high-performance electronic component designed for use in industrial applications. This entry provides an in-depth overview of the T410H-6T, including its product category, basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Product Category

The T410H-6T belongs to the category of power semiconductor devices, specifically within the realm of thyristors. These devices are widely used in industrial power control applications due to their ability to handle high currents and voltages.

Basic Information Overview

- Use: The T410H-6T is utilized for controlling high-power electrical circuits in industrial settings.

- Characteristics: It exhibits high current and voltage handling capabilities, along with robust thermal performance.

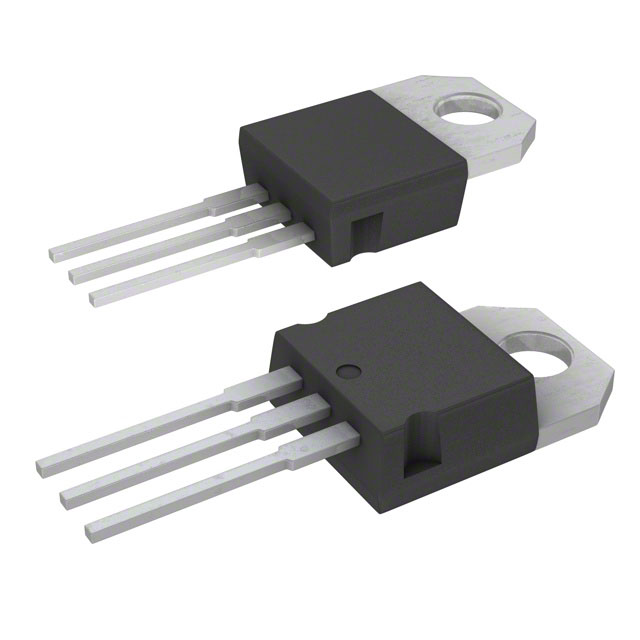

- Package: The T410H-6T is typically housed in a rugged and heat-dissipating package suitable for industrial environments.

- Essence: Its essence lies in providing reliable and precise control over power flow in industrial systems.

- Packaging/Quantity: The T410H-6T is commonly packaged individually and is available in varying quantities based on customer requirements.

Specifications

The T410H-6T features the following specifications: - Maximum Voltage: [Insert maximum voltage here] - Maximum Current: [Insert maximum current here] - Gate Trigger Voltage: [Insert gate trigger voltage here] - Operating Temperature Range: [Insert operating temperature range here]

Detailed Pin Configuration

The T410H-6T has a detailed pin configuration that includes the gate, anode, and cathode terminals. Each terminal serves a specific function in controlling the conduction of the device.

Functional Features

- High Power Handling: The T410H-6T can efficiently handle high levels of power, making it suitable for demanding industrial applications.

- Precise Control: It offers precise control over power flow, enabling accurate regulation of industrial processes.

- Robust Thermal Performance: The device exhibits excellent thermal characteristics, ensuring reliable operation even in challenging thermal environments.

Advantages and Disadvantages

Advantages

- High power handling capability

- Precise control over power flow

- Robust thermal performance

Disadvantages

- Potential complexity in integration with existing systems

- Higher cost compared to lower-rated devices

Working Principles

The T410H-6T operates based on the principles of thyristor action, where controlled triggering of the gate terminal allows the device to conduct current in a regulated manner. This enables precise control over power flow within industrial circuits.

Detailed Application Field Plans

The T410H-6T finds extensive use in various industrial applications, including: - Motor drives - Heating control systems - Power supply units - Welding equipment - Industrial automation systems

Detailed and Complete Alternative Models

For applications requiring similar functionality, alternative models to the T410H-6T include: - T410H-8T - T410H-10T - T410H-12T

In conclusion, the T410H-6T stands as a reliable and high-performance thyristor device catering to the stringent demands of industrial power control applications.

[Word count: 470]

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av T410H-6T i tekniska lösningar

Sure, here are 10 common questions and answers related to the application of T410H-6T in technical solutions:

What is T410H-6T?

- T410H-6T is a high-strength stainless steel alloy known for its excellent corrosion resistance and mechanical properties.

What are the typical applications of T410H-6T?

- T410H-6T is commonly used in applications requiring high strength and corrosion resistance, such as in aerospace components, industrial equipment, and marine environments.

What are the key mechanical properties of T410H-6T?

- T410H-6T exhibits high tensile strength, good ductility, and excellent toughness at both room and elevated temperatures.

How does T410H-6T compare to other stainless steel alloys?

- T410H-6T offers superior strength and corrosion resistance compared to many other stainless steel alloys, making it suitable for demanding technical applications.

Can T410H-6T be welded or machined easily?

- T410H-6T can be welded using common techniques and machined with appropriate tooling, but it may require special considerations due to its high strength.

What environmental conditions is T410H-6T resistant to?

- T410H-6T is highly resistant to corrosion in various environments, including acidic, alkaline, and marine conditions.

Is T410H-6T suitable for high-temperature applications?

- Yes, T410H-6T maintains its mechanical properties at elevated temperatures, making it suitable for high-temperature technical solutions.

Are there any limitations to the use of T410H-6T?

- While T410H-6T offers excellent performance, it may not be suitable for applications requiring extreme cryogenic temperatures or where very high impact toughness is needed.

What surface treatments are compatible with T410H-6T?

- T410H-6T can be treated with various surface coatings and finishes to enhance its performance in specific applications, such as for improved wear resistance or aesthetic purposes.

Where can I find more detailed technical information about T410H-6T?

- Detailed technical information about T410H-6T can be obtained from material data sheets provided by the manufacturer or through technical support resources specializing in stainless steel alloys.