T1635-600G Product Overview

Product Category

T1635-600G belongs to the category of power transistors.

Basic Information Overview

- Use: T1635-600G is used for amplifying or switching electronic signals in various applications.

- Characteristics: It exhibits high power handling capability, low on-state resistance, and fast switching speed.

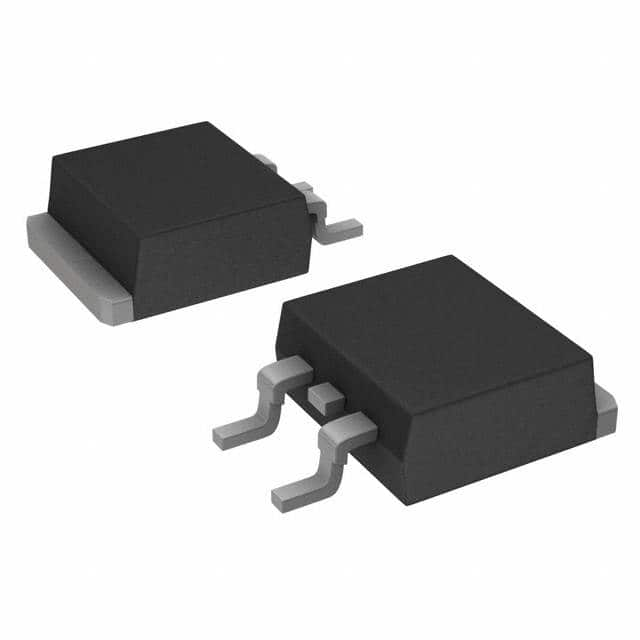

- Package: The product is available in a TO-220 package.

- Essence: T1635-600G is essential for power management and control in electronic circuits.

- Packaging/Quantity: Typically, T1635-600G is packaged individually and sold in quantities suitable for production or prototyping purposes.

Specifications

- Voltage Rating: 600V

- Current Rating: 40A

- Package Type: TO-220

- Mounting Type: Through Hole

- Operating Temperature: -55°C to 150°C

Detailed Pin Configuration

The detailed pin configuration of T1635-600G is as follows: 1. Collector (C) 2. Base (B) 3. Emitter (E)

Functional Features

- High voltage capability

- Low spread of dynamic parameters

- High switching speed

- Wide reverse bias safe operating area

Advantages and Disadvantages

Advantages

- High power handling capacity

- Fast switching speed

- Suitable for high voltage applications

Disadvantages

- Higher power dissipation compared to some alternative models

- Sensitive to overvoltage conditions

Working Principles

T1635-600G operates based on the principles of bipolar junction transistors, utilizing the control of current flow between its terminals to amplify or switch electronic signals.

Detailed Application Field Plans

T1635-600G finds extensive use in the following application fields: - Power supplies - Motor control - Inverters - Audio amplifiers - Lighting systems

Detailed and Complete Alternative Models

Some alternative models to T1635-600G include: - TIP3055 - MJ15003 - 2N3055 - MJE13005

In conclusion, T1635-600G is a versatile power transistor with high voltage capability and fast switching speed, making it suitable for a wide range of electronic applications.

[Word Count: 298]

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av T1635-600G i tekniska lösningar

Sure, here are 10 common questions and answers related to the application of T1635-600G in technical solutions:

Question: What is the maximum operating temperature for T1635-600G?

Answer: The maximum operating temperature for T1635-600G is 600 degrees Celsius.Question: Can T1635-600G be used in high voltage applications?

Answer: Yes, T1635-600G is suitable for high voltage applications.Question: What is the typical thermal conductivity of T1635-600G?

Answer: The typical thermal conductivity of T1635-600G is 1.5 W/m-K.Question: Is T1635-600G electrically insulating?

Answer: Yes, T1635-600G is electrically insulating, making it suitable for electrical applications.Question: Can T1635-600G be used for bonding electronic components to heat sinks?

Answer: Yes, T1635-600G is commonly used for bonding electronic components to heat sinks.Question: What is the shelf life of T1635-600G?

Answer: The shelf life of T1635-600G is typically 24 months when stored in its original packaging at room temperature.Question: Is T1635-600G compatible with aluminum surfaces?

Answer: Yes, T1635-600G is compatible with aluminum surfaces.Question: Can T1635-600G be applied using a dispensing tool?

Answer: Yes, T1635-600G can be applied using a dispensing tool for precise application.Question: Does T1635-600G require a curing process after application?

Answer: No, T1635-600G does not require a curing process, making it convenient for assembly processes.Question: What is the recommended thickness for applying T1635-600G?

Answer: The recommended thickness for applying T1635-600G is 0.1mm to 0.5mm for optimal thermal performance.