LCDA15: Product Overview and Specifications

Introduction

LCDA15 is a versatile integrated circuit that belongs to the category of analog-to-digital converters (ADCs). This device is widely used in various electronic applications due to its high precision, low power consumption, and compact package.

Basic Information Overview

- Category: Analog-to-Digital Converter

- Use: Conversion of analog signals to digital data

- Characteristics: High precision, low power consumption

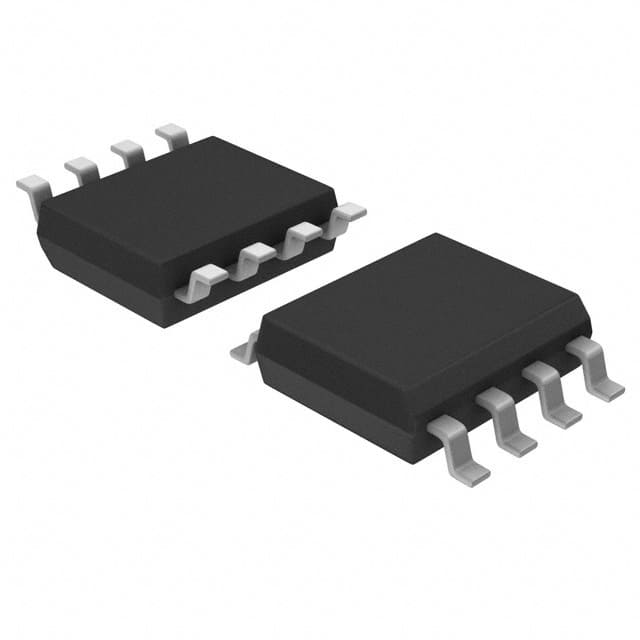

- Package: Compact form factor

- Essence: Accurate conversion of analog signals

- Packaging/Quantity: Available in various packaging options, typically sold in reels or tubes

Specifications

- Resolution: 12-bit

- Conversion Rate: Up to 1 MSPS (Million Samples Per Second)

- Input Voltage Range: 0V to Vref

- Power Supply: 2.7V to 5.5V

- Operating Temperature: -40°C to 85°C

- Interface: SPI (Serial Peripheral Interface)

Detailed Pin Configuration

The LCDA15 features a standard pin configuration with input, output, and control pins. The detailed pinout includes: 1. VDD - Power supply 2. VSS - Ground 3. REF+ - Positive reference voltage input 4. REF- - Negative reference voltage input 5. IN+ - Positive analog input 6. IN- - Negative analog input 7. SCK - Serial clock input 8. CS - Chip select input 9. DOUT - Digital output 10. DIN - Serial data input

Functional Features

- High-resolution conversion

- Low power consumption

- SPI interface for easy integration

- Wide operating voltage range

- Internal voltage reference

Advantages and Disadvantages

Advantages

- High precision conversion

- Low power consumption

- Compact form factor

- Wide operating temperature range

Disadvantages

- Limited maximum conversion rate

- Requires external reference voltage

Working Principles

The LCDA15 operates by sampling the analog input signal and converting it into a corresponding digital value using an internal ADC core. The digital output is then transmitted via the SPI interface for further processing by the host system.

Detailed Application Field Plans

The LCDA15 is well-suited for a wide range of applications including: - Industrial automation - Sensor interfaces - Portable instrumentation - Data acquisition systems - Battery-powered devices

Detailed and Complete Alternative Models

- LCDA16: Higher resolution (16-bit) version of LCDA15

- LCDA14: Lower resolution (10-bit) version with similar features

- LCDA20: Higher speed (2 MSPS) version for time-critical applications

In conclusion, the LCDA15 offers high precision analog-to-digital conversion in a compact and efficient package, making it an ideal choice for diverse electronic applications.

[Word Count: 398]

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av LCDA15 i tekniska lösningar

What is LCDA15?

- LCDA15 stands for Low Coefficient of Thermal Expansion Die Attach, which is a type of adhesive used in electronic packaging to minimize thermal stress.

How does LCDA15 help in technical solutions?

- LCDA15 helps by reducing the thermal stress on electronic components, improving reliability and performance in various technical applications.

What are the key properties of LCDA15?

- The key properties of LCDA15 include low coefficient of thermal expansion, high thermal conductivity, and excellent adhesion to various substrates.

In what technical applications is LCDA15 commonly used?

- LCDA15 is commonly used in semiconductor packaging, LED assembly, power modules, and other electronics where thermal management is critical.

What are the temperature range and operating conditions for LCDA15?

- LCDA15 typically operates within a temperature range of -50°C to 150°C and can withstand the thermal cycling and operational conditions of electronic devices.

How is LCDA15 applied in technical solutions?

- LCDA15 is applied using dispensing or printing methods, and then cured through a controlled heating process to achieve optimal bonding and thermal performance.

Are there any considerations for storage and handling of LCDA15?

- LCDA15 should be stored in a cool, dry place and handled according to the manufacturer's guidelines to maintain its effectiveness.

What are the advantages of using LCDA15 over other die attach materials?

- The advantages of LCDA15 include its ability to minimize thermal stress, improve thermal conductivity, and enhance the overall reliability of electronic components.

Are there any limitations or precautions when using LCDA15 in technical solutions?

- It's important to ensure proper curing and compatibility with specific substrates, and to consider any potential outgassing or contamination issues in sensitive applications.

Can LCDA15 be customized for specific technical requirements?

- Yes, manufacturers may offer customization options for LCDA15 to meet specific thermal, mechanical, or application-specific needs in technical solutions.