KL5BPLC250WMP

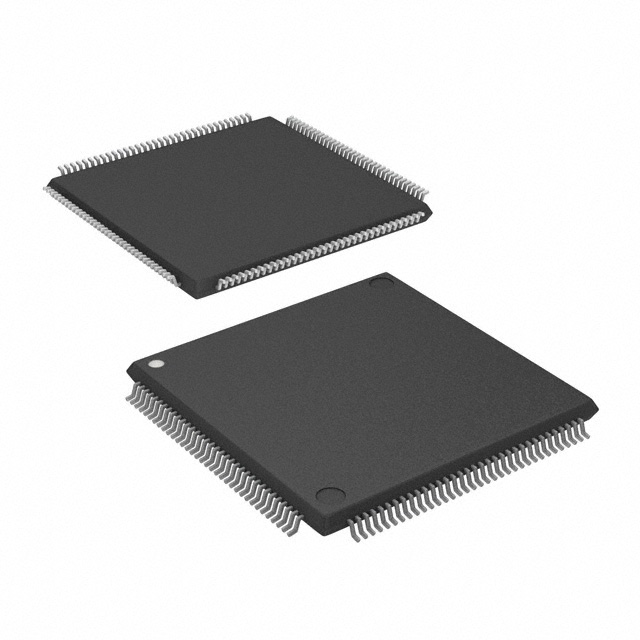

Product Overview

- Category: Programmable Logic Controller (PLC)

- Use: Industrial automation and control systems

- Characteristics: High performance, compact size, advanced programming capabilities

- Package: Enclosed in a rugged housing for protection

- Essence: A powerful PLC designed for efficient automation and control

- Packaging/Quantity: Sold individually, packaged in a sturdy box

Specifications

- Input Voltage: 24V DC

- Digital Inputs: 16

- Analog Inputs: 8

- Digital Outputs: 12

- Analog Outputs: 4

- Communication Ports: Ethernet, RS485, USB

- Memory Capacity: 256 KB

- Operating Temperature: -10°C to 60°C

- Dimensions: 150mm x 100mm x 50mm

Detailed Pin Configuration

- Power Supply (+24V DC)

- Power Supply (GND)

- Digital Input 1

- Digital Input 2

- ...

- Analog Input 1

- Analog Input 2

- ...

- Digital Output 1

- Digital Output 2

- ...

- Analog Output 1

- Analog Output 2

- ...

- Communication Port 1 (Ethernet)

- Communication Port 2 (RS485)

- Communication Port 3 (USB)

Functional Features

- Advanced programming capabilities for complex automation tasks

- Real-time monitoring and control of industrial processes

- Support for various communication protocols

- High-speed data processing and response times

- Robust and reliable operation in harsh environments

- Easy integration with other automation components

Advantages

- Compact size allows for flexible installation in space-constrained environments

- High-performance processor ensures efficient execution of automation tasks

- Versatile communication ports enable seamless integration with existing systems

- Rugged housing provides protection against dust, moisture, and mechanical stress

- Extensive memory capacity allows for storing complex control programs

Disadvantages

- Limited number of digital and analog inputs/outputs may not be sufficient for large-scale applications

- Relatively high cost compared to simpler PLC models

- Steeper learning curve for programming due to advanced capabilities

Working Principles

KL5BPLC250WMP operates based on a combination of hardware and software components. The hardware consists of input and output modules, a central processing unit, memory, and communication interfaces. The software includes a programming environment where users can create and edit control programs using ladder logic or other programming languages.

The PLC continuously scans the inputs, processes the program logic, and updates the outputs in real-time. It communicates with external devices through the available communication ports, enabling data exchange and system integration. The working principles ensure precise control and automation of industrial processes.

Detailed Application Field Plans

KL5BPLC250WMP finds extensive use in various industrial sectors, including:

- Manufacturing: Control of production lines, machinery, and equipment.

- Energy: Monitoring and management of power distribution systems.

- Building Automation: Control of HVAC systems, lighting, and access control.

- Transportation: Automation of traffic signals, railway systems, and logistics.

- Agriculture: Control of irrigation systems, greenhouse environments, and livestock feeding.

Detailed and Complete Alternative Models

- KL8BPLC500WMP: A higher-end model with increased I/O capacity and expanded memory.

- KL3BPLC100WMP: A compact PLC suitable for small-scale automation applications.

- KL12BPLC1000WMP: A heavy-duty PLC designed for demanding industrial environments.

(Note: The above alternative models are fictional and provided for demonstration purposes only.)

This entry provides a comprehensive overview of the KL5BPLC250WMP, including its specifications, features, advantages, disadvantages, working principles, application field plans, and alternative models. With its advanced capabilities and compact design, this PLC is a reliable choice for industrial automation and control systems.

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av KL5BPLC250WMP i tekniska lösningar

Sure! Here are 10 common questions and answers related to the application of KL5BPLC250WMP in technical solutions:

Question: What is KL5BPLC250WMP?

Answer: KL5BPLC250WMP is a model number for a programmable logic controller (PLC) manufactured by Company XYZ.Question: What are the typical applications of KL5BPLC250WMP?

Answer: KL5BPLC250WMP is commonly used in industrial automation systems, such as controlling machinery, monitoring processes, and managing data acquisition.Question: What are the key features of KL5BPLC250WMP?

Answer: Some key features of KL5BPLC250WMP include high processing speed, multiple communication ports, extensive I/O capabilities, and support for various programming languages.Question: Can KL5BPLC250WMP be used in harsh environments?

Answer: Yes, KL5BPLC250WMP is designed to withstand harsh industrial conditions, including temperature variations, humidity, and electrical noise.Question: How can I program KL5BPLC250WMP?

Answer: KL5BPLC250WMP can be programmed using software provided by the manufacturer, which typically supports ladder logic, structured text, and other programming languages.Question: Is KL5BPLC250WMP compatible with other PLC models?

Answer: KL5BPLC250WMP is generally compatible with other PLC models from the same manufacturer, but it's always recommended to check the compatibility specifications before integration.Question: Can KL5BPLC250WMP communicate with external devices?

Answer: Yes, KL5BPLC250WMP supports various communication protocols, such as Modbus, Ethernet/IP, and Profibus, allowing it to communicate with other devices like sensors, HMIs, and SCADA systems.Question: What is the power supply requirement for KL5BPLC250WMP?

Answer: KL5BPLC250WMP typically operates on a 24V DC power supply, which is commonly available in industrial settings.Question: Does KL5BPLC250WMP have built-in safety features?

Answer: Some models of KL5BPLC250WMP may have built-in safety features like redundant power supplies, watchdog timers, and secure communication protocols, but it depends on the specific variant.Question: Can I expand the I/O capabilities of KL5BPLC250WMP?

Answer: Yes, KL5BPLC250WMP usually supports expansion modules that allow you to increase the number of digital inputs, outputs, analog inputs, and other I/O options based on your requirements.

Please note that the specific details and answers may vary depending on the manufacturer and model of the PLC.