DUR30120 Product Overview

Introduction

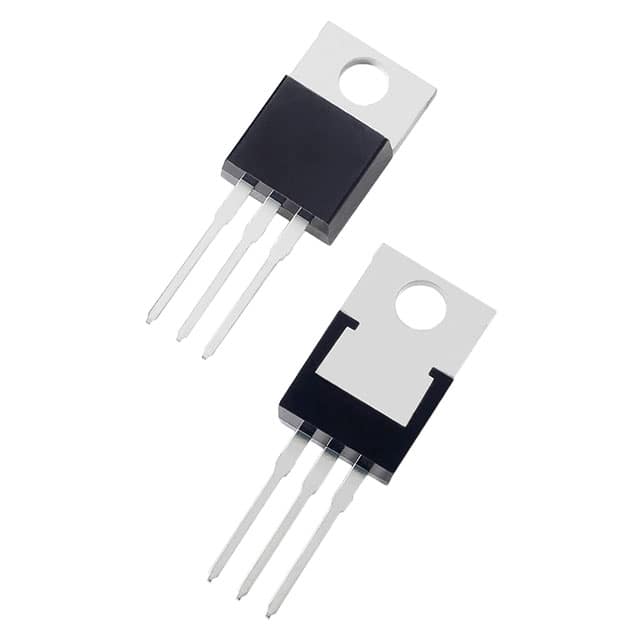

The DUR30120 is a versatile electronic component that belongs to the category of power rectifiers. This product is widely used in various electronic applications due to its unique characteristics and functional features.

Basic Information Overview

- Category: Power Rectifier

- Use: Conversion of alternating current (AC) to direct current (DC)

- Characteristics: High efficiency, low forward voltage drop, fast switching speed

- Package: TO-247

- Essence: Efficient power conversion

- Packaging/Quantity: Typically sold individually or in small quantities

Specifications

- Maximum Average Forward Current: 30A

- Maximum Peak Reverse Voltage: 1200V

- Forward Voltage Drop: 1.2V at 30A

- Reverse Recovery Time: 35ns

- Operating Temperature Range: -55°C to 175°C

Detailed Pin Configuration

The DUR30120 typically features three pins: 1. Anode 2. Cathode 3. Gate

Functional Features

- High efficiency power conversion

- Fast switching speed for improved performance

- Low forward voltage drop for reduced power loss

Advantages and Disadvantages

Advantages

- High efficiency

- Fast switching speed

- Low forward voltage drop

Disadvantages

- Higher cost compared to standard rectifiers

- Sensitive to overvoltage conditions

Working Principles

The DUR30120 operates based on the principle of rectification, converting AC input into DC output by allowing current flow in only one direction.

Detailed Application Field Plans

The DUR30120 is commonly used in the following applications: - Switching power supplies - Motor drives - Inverters - Welding equipment - Uninterruptible power supplies (UPS)

Detailed and Complete Alternative Models

- DUR30100

- DUR30150

- DUR30200

In summary, the DUR30120 power rectifier offers high efficiency and fast switching speed, making it suitable for various electronic applications. While it has advantages such as efficient power conversion, it also has limitations, including higher cost and sensitivity to overvoltage conditions. Understanding its specifications, pin configuration, working principles, and application field plans can help users make informed decisions when integrating this component into their designs.

Word Count: 310

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av DUR30120 i tekniska lösningar

What is DUR30120?

- DUR30120 is a technical standard for durability testing of materials and components used in various engineering applications.

Why is DUR30120 important in technical solutions?

- DUR30120 provides standardized testing procedures to ensure the durability and reliability of materials and components in technical solutions, helping to improve product quality and performance.

What types of materials and components does DUR30120 cover?

- DUR30120 covers a wide range of materials and components used in engineering applications, including metals, plastics, composites, and electronic components.

How is DUR30120 applied in technical solutions?

- DUR30120 is applied by conducting specific tests outlined in the standard, such as fatigue testing, corrosion resistance testing, and environmental exposure testing, to evaluate the durability of materials and components.

What are the benefits of following DUR30120 in technical solutions?

- Following DUR30120 helps ensure that materials and components meet industry standards for durability, leading to longer-lasting and more reliable technical solutions.

Are there any limitations to DUR30120?

- While DUR30120 provides valuable guidelines for durability testing, it may not cover every possible scenario or application, so additional testing and considerations may be necessary in some cases.

How does DUR30120 impact product development in technical solutions?

- DUR30120 can influence product design and material selection by providing data on the expected durability and performance of materials and components under specific conditions.

What are the common challenges in implementing DUR30120 in technical solutions?

- Challenges may include the cost and complexity of conducting the required tests, as well as interpreting and applying the test results to real-world applications.

Can DUR30120 be used for regulatory compliance in technical solutions?

- Yes, adherence to DUR30120 can demonstrate compliance with industry regulations and standards related to material durability and performance.

How often should materials and components be tested according to DUR30120 in technical solutions?

- The frequency of testing may vary depending on factors such as usage conditions, industry requirements, and product lifecycle, but regular testing is typically recommended to ensure ongoing durability and reliability.