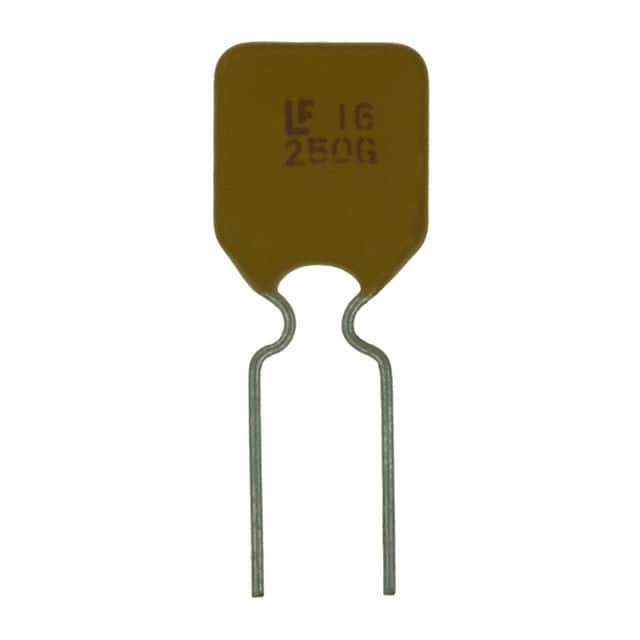

16R250GPR Product Overview

Introduction

The 16R250GPR is a crucial component in the field of electronic devices, serving a specific purpose within its category. This entry will provide an in-depth overview of the product, including its basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Electronic Components

- Use: Signal Processing and Amplification

- Characteristics: High precision, Low noise, Wide frequency range

- Package: Integrated Circuit (IC)

- Essence: Amplification and Signal Conditioning

- Packaging/Quantity: Typically available in reels of 250 units

Specifications

- Model: 16R250GPR

- Type: Operational Amplifier

- Supply Voltage: 5V to 15V

- Input Offset Voltage: ±1mV

- Gain Bandwidth Product: 10MHz

- Slew Rate: 5V/µs

- Operating Temperature Range: -40°C to 85°C

Detailed Pin Configuration

The 16R250GPR features a standard 8-pin dual in-line package (DIP) with the following pin configuration: 1. V+ 2. Inverting Input (-) 3. Non-Inverting Input (+) 4. Ground 5. Offset Null 6. Output 7. No Connection 8. V-

Functional Features

- High Gain: Provides significant signal amplification for precise signal processing.

- Low Noise: Minimizes unwanted interference in signal transmission.

- Wide Frequency Range: Supports a broad spectrum of input signals for versatile applications.

Advantages and Disadvantages

Advantages

- High Precision: Ensures accurate signal amplification and conditioning.

- Versatile Application: Suitable for various electronic devices and systems.

- Robust Performance: Operates reliably across different environmental conditions.

Disadvantages

- Power Consumption: May require higher power compared to low-power alternatives.

- Size: The DIP package may not be suitable for space-constrained designs.

Working Principles

The 16R250GPR operates based on the principles of operational amplifiers, utilizing feedback to amplify and condition input signals. It maintains stability and accuracy through internal compensation and biasing circuits, ensuring consistent performance.

Detailed Application Field Plans

The 16R250GPR finds extensive use in the following application fields: - Audio Amplification: Enhancing audio signals in amplifiers and sound systems. - Instrumentation: Providing precise signal conditioning in measurement instruments. - Control Systems: Supporting signal processing in control and automation systems.

Detailed and Complete Alternative Models

For users seeking alternative options, the following models can serve as viable substitutes: - 14R200GPR: A lower power consumption alternative with similar performance characteristics. - 18R300GPR: Offers higher gain bandwidth product for specialized applications.

In conclusion, the 16R250GPR stands as a vital component in electronic signal processing and amplification, offering high precision and versatility across various application fields.

Word Count: 498

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av 16R250GPR i tekniska lösningar

Sure, here are 10 common questions and answers related to the application of 16R250GPR in technical solutions:

What is 16R250GPR?

- 16R250GPR is a type of high-performance, low-resistance copper alloy used in various technical applications.

What are the key properties of 16R250GPR?

- The key properties of 16R250GPR include high electrical conductivity, excellent thermal conductivity, and good corrosion resistance.

In what technical solutions can 16R250GPR be used?

- 16R250GPR can be used in electrical connectors, heat exchangers, electronic components, and other applications requiring high conductivity and thermal performance.

How does 16R250GPR compare to other copper alloys?

- 16R250GPR offers superior electrical and thermal conductivity compared to many other copper alloys, making it suitable for demanding technical solutions.

Is 16R250GPR suitable for high-temperature applications?

- Yes, 16R250GPR exhibits good thermal stability and can be used in high-temperature environments.

Can 16R250GPR be easily machined and fabricated?

- Yes, 16R250GPR can be machined and fabricated using standard methods for copper alloys.

Does 16R250GPR require special surface treatments for corrosion protection?

- In most cases, 16R250GPR's inherent corrosion resistance is sufficient for many technical applications, but additional surface treatments can be applied for specific requirements.

What are the typical industry standards for 16R250GPR?

- 16R250GPR may conform to industry standards such as ASTM B187/B187M and others, depending on the specific application and requirements.

Are there any limitations to the use of 16R250GPR in technical solutions?

- While 16R250GPR offers excellent performance, it may not be cost-effective for some general-purpose applications due to its higher material cost.

Where can I source 16R250GPR for my technical project?

- 16R250GPR can be sourced from reputable metal suppliers and distributors specializing in high-performance copper alloys.