ALD2301CSAL

Product Overview

Category: Integrated Circuit (IC)

Use: ALD2301CSAL is a high-performance operational amplifier designed for various applications in electronic circuits.

Characteristics: - Low input offset voltage - High gain bandwidth product - Low noise - Wide supply voltage range

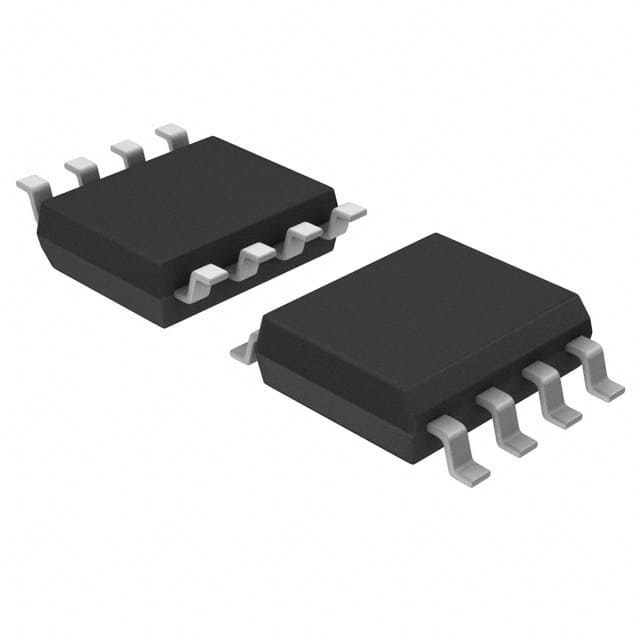

Package: ALD2301CSAL is available in a small outline package (SOP) with 8 pins.

Essence: The essence of ALD2301CSAL lies in its ability to amplify and process electrical signals accurately and efficiently.

Packaging/Quantity: ALD2301CSAL is typically sold in reels containing 250 units per reel.

Specifications

- Supply Voltage Range: ±2V to ±18V

- Input Offset Voltage: 0.5mV (maximum)

- Gain Bandwidth Product: 10MHz (typical)

- Input Bias Current: 50nA (maximum)

- Output Voltage Swing: ±12V (minimum)

- Slew Rate: 5V/µs (typical)

Pin Configuration

ALD2301CSAL features the following pin configuration:

```

| | --| V- OUT |-- --| V+ IN- |-- --| NC IN+ |-- --| VCC NC |-- --| GND NC |-- --| NC NC |-- |___________| ```

Functional Features

- Low input offset voltage ensures accurate signal amplification.

- High gain bandwidth product allows for amplification of high-frequency signals.

- Low noise performance ensures minimal interference in signal processing.

- Wide supply voltage range provides flexibility in various circuit designs.

Advantages and Disadvantages

Advantages: - Accurate signal amplification - High-frequency signal amplification capability - Low noise performance - Wide supply voltage range

Disadvantages: - Limited output voltage swing compared to some other models - Relatively higher input bias current

Working Principles

ALD2301CSAL operates based on the principles of operational amplifiers. It utilizes differential inputs and a high-gain amplifier to amplify and process electrical signals. The input stage provides low offset voltage, while the gain stage amplifies the signal with minimal distortion. The output stage ensures proper voltage swing and drives the load.

Application Field Plans

ALD2301CSAL finds applications in various electronic circuits, including: - Audio amplifiers - Instrumentation amplifiers - Active filters - Signal conditioning circuits - Data acquisition systems

Alternative Models

Some alternative models that can be considered as alternatives to ALD2301CSAL are: - AD8628 - LM358 - TL071 - OPA2134 - LT1498

These models offer similar functionalities and can be used as substitutes depending on specific requirements.

Word count: 314 words

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av ALD2301CSAL i tekniska lösningar

Sure! Here are 10 common questions and answers related to the application of ALD2301CSAL in technical solutions:

Q1: What is ALD2301CSAL? A1: ALD2301CSAL is a specific model or type of ALD (Atomic Layer Deposition) equipment used for thin film deposition in technical applications.

Q2: What are the key features of ALD2301CSAL? A2: Some key features of ALD2301CSAL include precise control over film thickness, excellent uniformity, high deposition rates, and compatibility with various materials.

Q3: What technical solutions can ALD2301CSAL be applied to? A3: ALD2301CSAL can be applied to various technical solutions such as semiconductor manufacturing, solar cell production, microelectronics, optical coatings, and nanotechnology research.

Q4: How does ALD2301CSAL achieve precise film thickness control? A4: ALD2301CSAL achieves precise film thickness control by utilizing a sequential, self-limiting process where individual atomic layers are deposited one at a time.

Q5: Can ALD2301CSAL deposit films on different types of substrates? A5: Yes, ALD2301CSAL is designed to deposit films on a wide range of substrates including silicon wafers, glass, metals, ceramics, and polymers.

Q6: What are the advantages of using ALD2301CSAL in semiconductor manufacturing? A6: ALD2301CSAL offers several advantages in semiconductor manufacturing, including conformal coating, excellent step coverage, low defect density, and the ability to deposit ultra-thin films.

Q7: Does ALD2301CSAL require any special gases or precursors? A7: Yes, ALD2301CSAL typically requires specific precursor chemicals and gases that are compatible with the desired film material. These precursors can vary depending on the application.

Q8: Can ALD2301CSAL be integrated into existing manufacturing processes? A8: Yes, ALD2301CSAL can be integrated into existing manufacturing processes as it is designed to be compatible with standard cleanroom environments and industry-standard equipment.

Q9: What safety precautions should be taken when operating ALD2301CSAL? A9: When operating ALD2301CSAL, it is important to follow all safety guidelines provided by the manufacturer, including proper handling of chemicals, wearing appropriate personal protective equipment, and ensuring proper ventilation.

Q10: Are there any maintenance requirements for ALD2301CSAL? A10: Yes, like any other technical equipment, ALD2301CSAL requires regular maintenance, such as cleaning, calibration, and replacement of consumables, to ensure optimal performance and longevity.

Please note that the specific questions and answers may vary depending on the context and requirements of the technical solutions being discussed.