ALD2301CPAL

Product Overview

Category: Integrated Circuit (IC)

Use: The ALD2301CPAL is a versatile integrated circuit primarily used for signal conditioning and amplification in various electronic applications.

Characteristics: - High precision and accuracy - Low power consumption - Wide operating voltage range - Compact size - Excellent noise performance

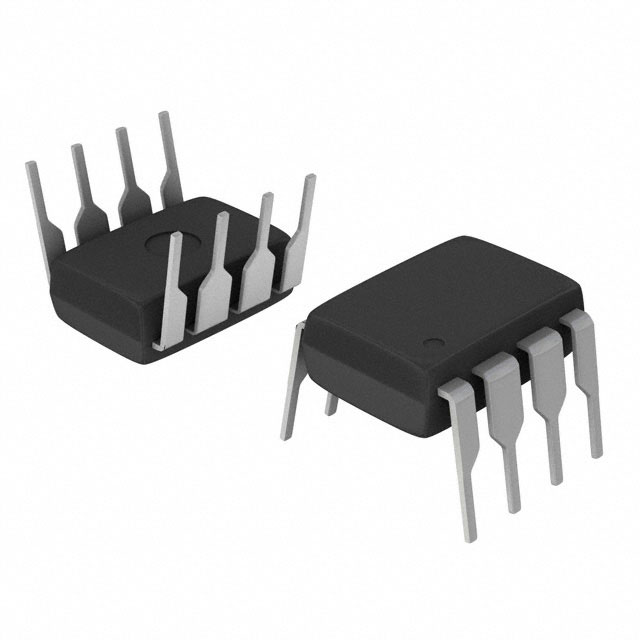

Package: The ALD2301CPAL is available in a small outline package (SOP) with 8 pins.

Essence: This IC is designed to enhance the quality and reliability of analog signals by providing amplification, filtering, and other signal conditioning functions.

Packaging/Quantity: The ALD2301CPAL is typically sold in reels or tubes containing a quantity of 1000 units per package.

Specifications

The specifications of the ALD2301CPAL are as follows:

- Supply Voltage Range: 2.7V to 5.5V

- Operating Temperature Range: -40°C to +85°C

- Gain Bandwidth Product: 10 MHz

- Input Offset Voltage: ±1 mV

- Input Bias Current: ±10 nA

- Output Voltage Swing: ±4 V

- Quiescent Current: 500 µA

Pin Configuration

The ALD2301CPAL features the following pin configuration:

```

| | --| V+ OUT |-- Pin 1: Positive Power Supply (V+) --| IN- GND |-- Pin 2: Inverting Input (-) --| IN+ NC |-- Pin 3: Non-Inverting Input (+) --| V- NC |-- Pin 4: Negative Power Supply (V-) --| NC NC |-- Pin 5: Not Connected --| NC NC |-- Pin 6: Not Connected --| NC NC |-- Pin 7: Not Connected --| NC VREF |-- Pin 8: Reference Voltage (VREF) |___________| ```

Functional Features

The ALD2301CPAL offers the following functional features:

- Differential input configuration for improved common-mode rejection ratio (CMRR)

- Adjustable gain through external resistors

- Low input offset voltage for accurate signal amplification

- Rail-to-rail output swing for maximum signal range

- Built-in protection against electrostatic discharge (ESD)

Advantages and Disadvantages

Advantages: - High precision amplification - Wide operating voltage range - Low power consumption - Compact size for space-constrained applications - Excellent noise performance for clean signal amplification

Disadvantages: - Limited number of pins for additional functionality - Requires external components for specific application requirements

Working Principles

The ALD2301CPAL operates based on the principles of operational amplifiers. It utilizes a differential input stage, followed by a gain stage and an output buffer. The differential input allows for precise amplification of small signals while rejecting common-mode noise. The gain can be adjusted using external resistors to suit different application requirements. The output buffer ensures a high output swing with minimal distortion.

Application Field Plans

The ALD2301CPAL finds applications in various fields, including but not limited to: - Medical devices - Industrial automation - Test and measurement equipment - Audio amplification systems - Sensor signal conditioning

Alternative Models

For users seeking alternative options, the following integrated circuits can be considered: - ALD2302CPAL - ALD2303CPAL - ALD2304CPAL - ALD2305CPAL

These models offer similar functionality and characteristics to the ALD2301CPAL, providing flexibility in choosing the most suitable IC for specific applications.

In conclusion, the ALD2301CPAL is a highly versatile integrated circuit that excels in signal conditioning and amplification. Its compact size, low power consumption, and excellent noise performance make it an ideal choice for various electronic applications.

Lista 10 Vanliga frågor och svar relaterade till tillämpningen av ALD2301CPAL i tekniska lösningar

Sure! Here are 10 common questions and answers related to the application of ALD2301CPAL in technical solutions:

1. What is ALD2301CPAL? - ALD2301CPAL is a specific model or type of ALD (Atomic Layer Deposition) equipment used for thin film deposition in technical applications.

2. What are the key features of ALD2301CPAL? - The key features of ALD2301CPAL include precise control over film thickness, excellent uniformity, high deposition rates, and compatibility with various materials.

3. What are the typical applications of ALD2301CPAL? - ALD2301CPAL is commonly used in semiconductor manufacturing, nanotechnology research, optical coatings, energy storage devices, and other industries requiring precise thin film deposition.

4. How does ALD2301CPAL work? - ALD2301CPAL works by sequentially exposing a substrate to alternating precursor gases, creating a self-limiting reaction that deposits a single atomic layer at a time. This process ensures precise control over film thickness and composition.

5. What types of substrates can be used with ALD2301CPAL? - ALD2301CPAL can be used with a wide range of substrates, including silicon wafers, glass, metals, ceramics, and polymers.

6. What are the advantages of using ALD2301CPAL over other deposition techniques? - ALD2301CPAL offers several advantages, such as excellent conformality on complex 3D structures, low temperature processing, high film quality, and the ability to deposit ultra-thin films.

7. Can ALD2301CPAL be integrated into existing manufacturing processes? - Yes, ALD2301CPAL can be easily integrated into existing manufacturing processes due to its compatibility with standard cleanroom environments and process control systems.

8. What are the safety considerations when using ALD2301CPAL? - Safety considerations include proper handling of precursor gases, ensuring adequate ventilation, and following manufacturer guidelines for equipment operation and maintenance.

9. How can I optimize the deposition process using ALD2301CPAL? - Optimization can be achieved by adjusting process parameters such as precursor flow rates, temperature, pressure, and exposure time. It is recommended to consult the equipment manual or seek expert advice for specific applications.

10. Are there any limitations or challenges associated with ALD2301CPAL? - Some limitations include longer deposition times compared to other techniques, potential precursor waste, and the need for careful selection of precursor materials for specific applications. However, these challenges can be overcome with proper process optimization and material selection.

Please note that the answers provided here are general and may vary depending on the specific requirements and capabilities of ALD2301CPAL.